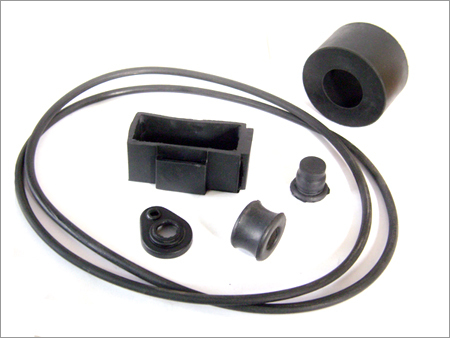

Rubber Moulded Parts

200 INR

Product Details:

- Resistance level High abrasion, oil, and chemical resistance

- Product Type Rubber Moulded Parts

- Tolerance 0.05 mm

- Material EPDM, NBR, Neoprene, silicone, NR

- Thickness 1 mm to 30 mm

- Thermal Conductivity Low

- Length Custom lengths available

- Click to View more

X

Rubber Moulded Parts Price And Quantity

- 200.00 - 400.00 INR

- 10 Piece

- 200 INR

Rubber Moulded Parts Product Specifications

- Smooth, matte, or textured

- 1 mm to 30 mm

- EPDM, NBR, Neoprene, silicone, NR

- Low

- Custom lengths available

- Below 1%

- Available on request

- Below 1%

- Precision Moulded

- Up to 300 mm

- High abrasion, oil, and chemical resistance

- Less than 5%

- Automotive, industrial machinery, electrical components, sealing, vibration dampening

- Rubber Moulded Parts

- Gasket, seal, buffer, bushing, washer

- Black or as specified

- Customizable as per requirement

- Negligible

- Depends on size and design

- Available in various sizes

- 0.05 mm

Rubber Moulded Parts Trade Information

- 10 Days

- Yes

- Contact us for information regarding our sample policy

- Box pecking

- All India

- ISO 9001:2015

Product Description

Fostered with immense years of industry experience and market understanding, we are offering a wide gamut of Rubber Moulded Parts. These parts are widely used in the automotive, automobile and electrical industries for various purposes. Offered parts are manufactured using premium grade rubber and advanced technology in line with the set quality standards. Also, we offer these Rubber Moulded Parts in various specific options as per the diverse requirement of our clients.

Features:

-

Easy installation

-

Flexibility

-

Maintenance free

-

Durable finish standards

Versatile Applications Across Industries

Rubber moulded parts serve critical functions everywhere from automotive systems to complex industrial machinery and electrical assemblies. Their advanced materials and designs provide durable solutions for sealing, vibration dampening, and insulation. Whether you require gaskets for engines or bushings for machinery, these components conform to custom specifications, supporting a wide range of operational demands.

Precision Engineering and Customization

Our parts are manufactured with exceptional accuracy, maintaining tolerances as fine as 0.05 mm. Customers can specify size, thickness, color, style, and material based on project needs. With diameters up to 300 mm and lengths tailored per order, we ensure that each component integrates seamlessly into your equipment, guaranteeing optimal performance and reliability.

FAQs of Rubber Moulded Parts:

Q: How are your rubber moulded parts typically used in different industries?

A: These rubber moulded parts are employed for sealing, vibration dampening, cushioning, and insulating in automotive systems, industrial machinery, and electrical components. Their high resistance to abrasion, oils, and chemicals makes them ideal for harsh environmentsthey can function as gaskets, seals, buffers, bushings, or washers.Q: What materials are used to manufacture these rubber moulded parts, and what benefits do they provide?

A: We offer parts made from EPDM, NBR, neoprene, silicone, and natural rubber (available on request). Each material provides unique benefits, such as superior resistance to heat, chemicals, oils, and abrasion, ensuring high durability and performance for specific applications.Q: What is the process for customizing rubber moulded parts for my specific requirements?

A: Customization begins with your specifications regarding size, width, thickness, color, and material. Our precision moulding process ensures tight tolerances and tailored dimensions, with surface finishes available in smooth, matte, or textured. This approach guarantees components that fit your equipment and perform reliably.Q: Where can I use these rubber moulded parts for maximum benefit?

A: These parts excel in automotive engines, industrial machinery housings, electronic device seals, and other assemblies requiring robust sealing, damping, or insulation. Their adaptability and resistance make them invaluable wherever performance and protection are essential.Q: When should I consider replacing or upgrading rubber moulded parts in my machinery?

A: Its advisable to replace or upgrade these parts whenever you notice signs of wear, reduced performance, or when changing operational requirements demand improved material properties or tighter tolerances. Our high-quality components can significantly enhance system longevity and efficiency.Q: How do these parts resist water and extreme conditions?

A: Featuring negligible water absorption and low thermal conductivity, our rubber parts offer excellent performance in humid or temperature-variable environments. Their chemical and abrasion resistance also ensures longevity in challenging operational settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email